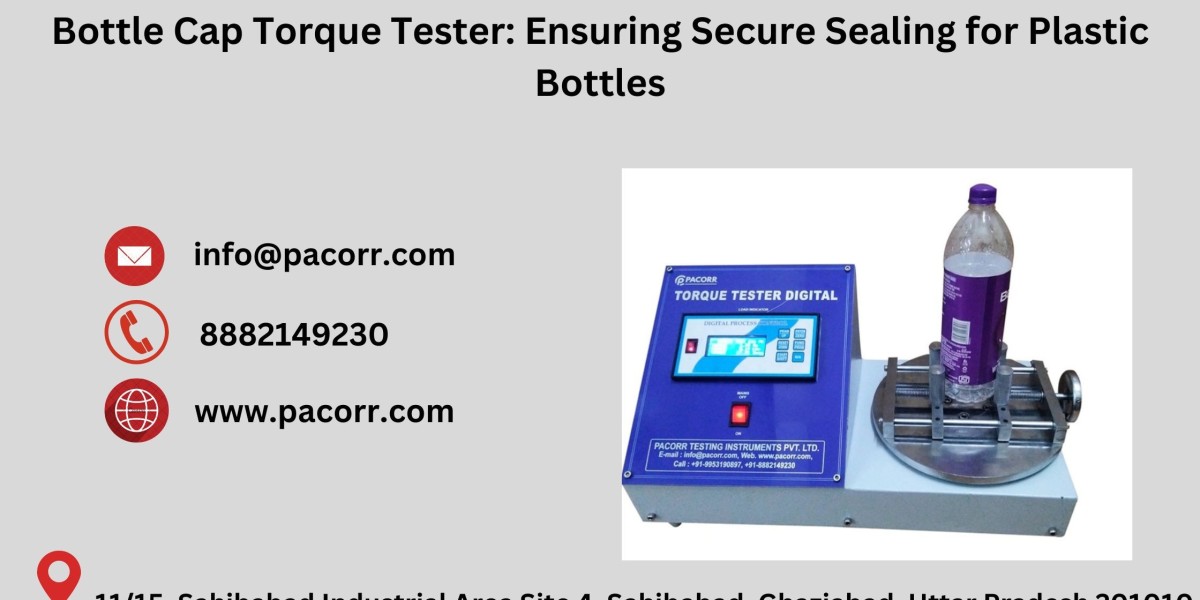

Bottle Cap Torque Tester: Ensuring Precision in Packaging Performance

In todays competitive market, packaging plays a critical role in ensuring product integrity and brand value. Among various aspects of packaging, maintaining consistent torque on bottle caps is essential for preserving product quality and enhancing user experience. At pacorr.com, the Bottle Cap Torque Tester emerges as a reliable solution to measure and maintain optimal torque in bottle closures.

Introduction to Bottle Cap Torque Testing

Bottle caps serve as a critical barrier, protecting the contents of bottles from external factors like contamination and leakage. Ensuring that the torque used to tighten or loosen these caps is consistent is vital for both product safety and consumer convenience. Torque that is too high may result in consumer dissatisfaction due to difficulty in opening the bottle, while torque that is too low can lead to leaks and compromised product quality.

The Bottle Cap Torque Tester Price from Pacorr offers a precise and reliable way to measure torque values, enabling manufacturers to meet packaging standards and deliver quality assurance.

Features of Pacorr's Bottle Cap Torque Tester

- Accurate Measurements

The tester is equipped with advanced sensors and technology to provide accurate torque readings, ensuring precise quality control. - User-Friendly Design

Pacorr's Bottle Cap Torque Tester is designed for ease of operation, allowing operators to test a wide range of bottle caps effortlessly. - Versatile Application

It supports various industries, including beverages, pharmaceuticals, cosmetics, and chemicals, where proper torque application is crucial. - Durability and Reliability

Built with robust materials, the tester ensures long-term reliability, even under demanding industrial environments.

Applications of the Bottle Cap Torque Tester

- Beverage Industry

Ensures that caps are sealed tightly to prevent carbonation loss or leakage. - Pharmaceuticals

Guarantees tamper-evident closures meet the required torque levels, ensuring consumer safety. - Cosmetics Industry

Maintains the integrity of packaging to avoid spillage or product wastage. - Food Industry

Checks the torque of caps on food jars and bottles to prevent spoilage due to air leakage.

Benefits of Using Pacorr's Bottle Cap Torque Tester

- Enhanced Quality Control

Achieve consistent results across batches, reducing customer complaints and product returns. - Regulatory Compliance

Meet industry standards and regulations for packaging quality with accurate torque testing. - Cost Efficiency

Minimize material wastage and improve productivity by identifying torque issues early in the production process. - Improved Customer Satisfaction

Ensure caps are easy to open yet securely sealed, enhancing the overall user experience.

Why Choose Pacorr for Bottle Cap Torque Testing?

At pacorr.com, we specialize in delivering state-of-the-art testing instruments designed to meet the diverse needs of global industries. The Bottle cap torque tester manufacturers is a testament to our commitment to innovation, quality, and customer satisfaction. With cutting-edge technology and a customer-centric approach, we ensure you get the most reliable testing solutions.

Conclusion

The Bottle Cap Torque Tester is a crucial tool for maintaining packaging quality and safeguarding product integrity. By incorporating this tester into your quality control process, you can enhance your brand reputation and ensure customer satisfaction. Visit pacorr.com today to learn more about our range of testing instruments and how they can add value to your production line.